How to select the correct pre charging resistor? Please take a look at the analysis

22-08-12

What is a pre charged resistor? Simply put, in the initial stage of power on, the power supply needs to charge the capacitor. If not limited, excessive charging current can cause significant impact on relays, rectifier devices, and the capacitor to be charged. Therefore, a resistor is used to limit the current. The resistor used here is the pre charging resistor.

It has been nearly 180 years since the birth of the first electric vehicle in 1834 and the emergence of new energy vehicles at major international car exhibitions in 2011. After nearly two centuries of twists and turns in development, new energy vehicles have made unprecedented breakthroughs in terms of types, technologies, and market share. As a subdivision of electric vehicles, hybrid electric vehicles and pure electric vehicles, fuel cell vehicles dominate the development process of new energy vehicles and have received more attention than other types of vehicles. They are characterized by high efficiency, energy conservation, low noise, and no pollution, It has become a new trend in the development of the automotive industry both domestically and internationally. Although the power supply, drive, and control systems used in new energy vehicles are not significantly different from industrial applications in theory, due to the high requirements for safety, stability, reliability, and other aspects in different operating environments, electric vehicles need to take more comprehensive and serious consideration in circuit design and component selection. As a battery management system for the power part of electric vehicles, Its safety, reliability, and stability are undoubtedly key to the overall performance of the vehicle. This article analyzes and discusses the selection of pre charging resistors in battery management systems.

The battery management system of new energy vehicles often involves high-voltage pre charging, because the motor controller (also known as the inverter) has a large bus capacitance. In the case of cold start without pre charging, if the main relay is directly connected, the high voltage of the battery will be directly loaded onto the empty bus capacitor, which is equivalent to an instantaneous short circuit. The extremely high instantaneous current will damage the relay. After adding a pre charging battery, the bus capacitor is pre charged through the pre charging circuit, so that the current when the main circuit is connected can be controlled within a safe range to ensure the normal operation of the system. The pre charged battery is an indispensable and crucial component in the battery management system. So how should we analyze and choose the appropriate resistor for this application?

Before selecting a resistor, we first need to have a clear understanding of the operating conditions and parameter requirements:

1. High voltage battery power output voltage

2. Rated current of relay

3. Bus capacitance value

4. Possible maximum ambient temperature at startup

5. Temperature rise requirements for resistors

6. The voltage required for capacitor pre charging

7. Time required to reach charging voltage

8. Single pulse or continuous pulse?

9. If it is a continuous pulse, what are the number of times the resistance can resist continuous pulses and the interval time between pulses?

10. When the battery is abused, the duration of time required for the resistor to remain in normal working condition

11. Installation structure and wiring method of resistors

12. Requirements for insulation voltage

After understanding the detailed working conditions and parameters, it is necessary to perform some basic calculations. Normally, pre charging is required to be completed within 500ms. In such a short period of time, the high heat generated by the current passing through the resistor wire or resistor body cannot be absorbed by the resistor skeleton, and the resistor wire or resistor body itself will have to bear the majority of the energy in the pulse. Therefore, we need to first calculate the pulse energy at startup, and then choose a suitable resistor scheme.

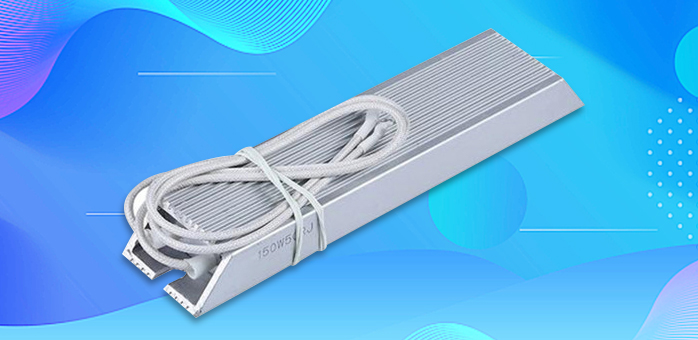

After determining the relevant technical parameters of the pre charging resistor, it is still necessary to choose a suitable resistor manufacturer. Currently, there are many manufacturers of pre charging resistors in the market, both large and small. We often hear cases of customers' serious failure or even explosion of pre charging resistors. This is actually closely related to the actual strength of selecting the manufacturer and the materials, processes, and control aspects of using the resistor. Therefore, it is very important to choose a strong and guaranteed Guangjia!